HeatWork casts concrete on top of the bridge tower

Facsimile from Fremover 24th of November 2016, by Fritz Hansen

The Chinese company constructing the Hålogaland bridge performed an online search for solutions

Google brought them to a company from Narvik

The Chinese entrepreneur company SRBG are pressed for time with regards to the Hålogaland bridge.

After searching online for solutions to challenges with winter casting, they found the solution – in Narvik.

One of the people who isn’t surprised that a solution to the challenges was found locally is the CEO of Visinor Rehab, Terje Feragen. “There is an extremely large and competent concrete industry in this region,” he claims. Visinor has had – and has projects across the country, and therefore has a good overview of the professional environment on a national level.

Not discovered

About what can be found in Narvik, he has no doubts:

“It is particularly strong. I’m referring to both consultants, entrepreneurs, and other professional environments,” he says.

Among the latter are, not least, the University of Tromsø in Narvik and the research and innovation company NORUT.

“If we haven’t completely succeeded in bringing this out nationally, and also that northern Norwegian projects are assigned to companies foreign to the region. Can be explained by the fact that procurement offices in large, public businesses have their offices in Oslo. And we don’t show up on their radar,” suggests Terje Feragen.

Competence was in this case both discovered and recognized by SRBG after searching for good solutions for the casting work on the Hålogaland bridge.

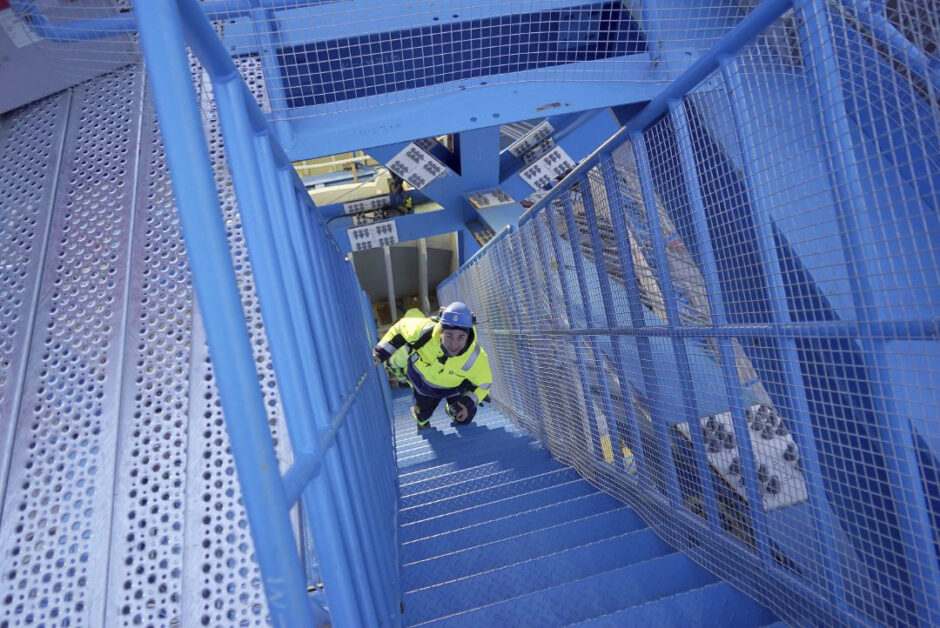

Airy

So on Tuesday, a HeatWork aggregate was lifted almost 200 meters into the air so it could be used on the top of the bridge’s towers.

Vitaljus Zubrickas and Nikola Gerber from Visinor Rehab were contracted to assist during this particularly airy endeavor.

Sales Manager at HeatWork, Tommy Larsen, says this about what happened when they received a visit from a representative for the Chinese entrepreneur: “He had searched online for solutions to the challenges of concrete casting during the winter. There, he found assessments of our product. The surprise was considerate when he discovered that it was located in Narvik, just a short ways from where the bridge is bring constructed.”

After the representative received a presentation of the equipment, he made his decision. “He wanted to use it.”

Long experience

“We therefore sent him to Visinor. A company who has long experience with using the equipment. Among other things, in conjunction with mast foundations to the new power line from Ofoten to Balsfjord.”

Terje Feragen confirms Tommy Larsen’s statement that a lot of time can be saved by adding heat.

Tommy Larsen describes how important temperature is in this way:

“I have a standard which I hold myself to. It basically states that it takes 55 days to achieve 75% casting of concrete if the temperature is minus one degree. If the temperature is 21 degrees, it only takes 8 days.”

Long break

Terje Feragen adds: “The most important thing is to achieve a stable temperature in the casting. If it’s under negative 5 degrees, casting shouldn’t take place. So they therefore risk having to wait until the spring if there weren’t methods to add heat.” And in this case, stable heat. “It is probably still more expensive to cast in the winter than in the summer. But with the equipment that we’ve used in the foundations, we always know what both the internal and external temperatures are during the casting process. The ‘trick’ is that sensors are cast into the concrete, which gives us total control over the entire process,” he explains.

“There are multiple ways to add heat, but if there is too much heat added locally, it can ruin the concrete,” he points out.