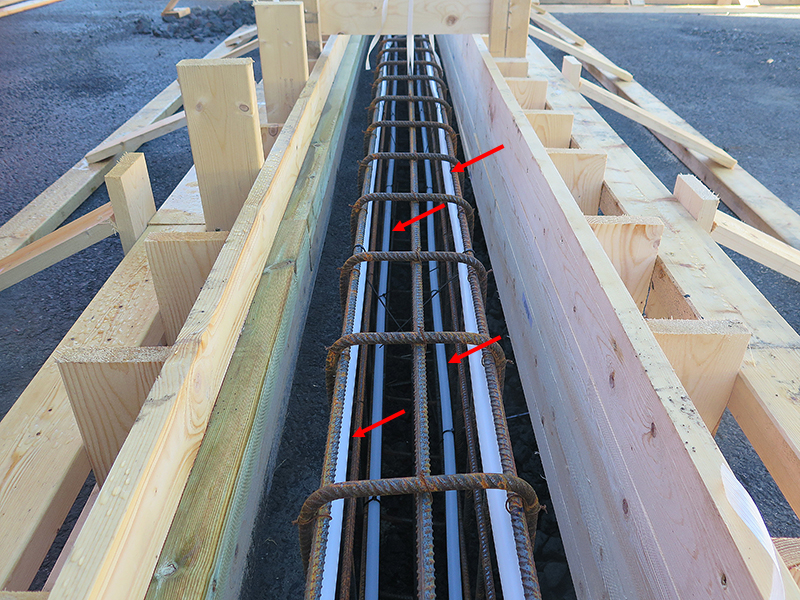

Hardening concrete – shelf/perimeter foundation wall

- Pert pipes are attached to the reinforcement with CC 30 cm

- They are attached to the HeatWork machine, which delivers 30°C liquid through the pipes

- The concrete is brought to the ideal temperature for hardening and quality

- The solution is time-saving, and the project can maintain necessary progress in any outdoor temperature

Hardening concrete – shelf/perimeter foundation wall

- HeatWork hoses are inserted into the formwork

- HeatWork winter mat is placed over the formwork

- The hoses are attached to the HeatWork machine, which delivers the desired temperature in the hoses

- The concrete is brought to the ideal temperature for hardening and quality

- The solution is time-saving, and the project can maintain necessary progress in any outdoor temperature

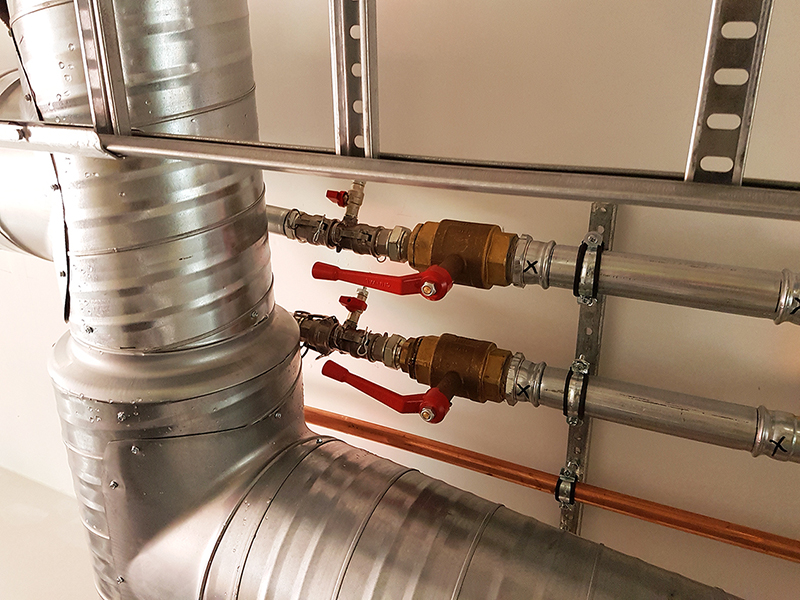

Temporary operation of water-based underfloor heating systems

Drying concrete prior to laying flooring

Building heating

- Prosjekt Omsorgsbolig, Nilsen og Haukland AS

- Drying out the concrete before laying flooring / building heating

- CliWi 100 kW working on a 1,000 m2 floor heating facility

- 4 months since the floor was cast, but there is still over 85% moisture in the concrete

Visinor Rehab AS has begun casting mast foundations

The entrepreneur keeps operations running under difficult conditions, with negatives temperatures both above and below the ground. The prize is increased length of season, less absences, and increased effectivity!

Concrete projects that we help you solve independent of temperature are:

- Floor and foundation casting

- The rehabilitation of, for example, docks or bridges

- Preheating or thawing of soil

- Thawing of snow or ground frost

- Heating rock being grouting

- Correct temperature for hardening

- and more

Contact us by telephone (76 96 58 90) for more information about the project.